It takes more than just advanced machinery to manufacture large propellers for ships, it also requires the manufacturer to have strong casting technology, specialized processing methods, and an experienced technical team.

Many recognized marine equipment suppliers like Wartsila, Masson have their propeller partners in China. It is the very same partners that allow Fountom to be capable of designing, and manufacturing medium to giant propellers with diameters up to 8 meters for various types of vessels, at more reasonable costs.

What kind of propellers can be ordered from Fountom

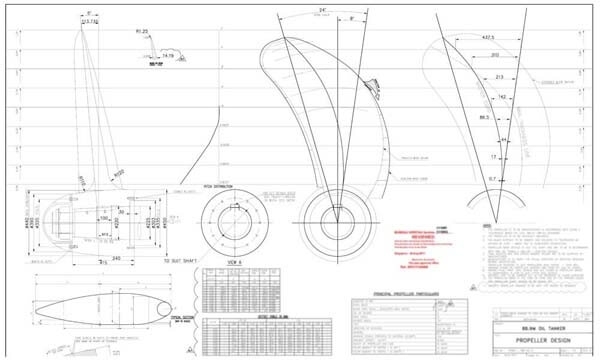

Fountom designs and manufactures different types of fixed pitch propellers and shafts, shafting accessories for various vessels, which are in the scope of:

Fountom designs and manufactures different types of fixed pitch propellers and shafts, shafting accessories for various vessels, which are in the scope of:

Propeller Diameter: 800~8000mm;

Blade Design Type: Kaplan, MAU, B;

Material: Ni-Al Bronze/Copper (Cu1, Cu3), Stainless steel;

Propeller Blade Number: 4~6 blades;

Blades Dimensional Tolerances: better than ISO 481;

Available Shipping Class: ABS, BV, CCS, DNV-GL, RINA, NK, KR;

Vessel Types: container vessels, tankers, bulk carriers, dry cargo vessels, passenger liners, fishing trawlers, tugboats, etc.

Outstanding features of Fountom propellers

Optimal propeller efficiency

Propeller is the key to maximizing power efficiency, Fountom takes it through design, manufacturing, and test processes, and the radial distribution of circulation, resembling lift or thrust shall be specified to obtain the optimum efficiency.

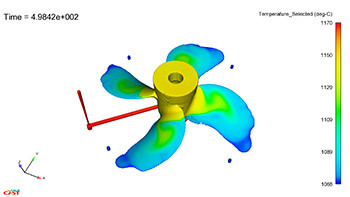

Noise, vibration and cavitation control

Simulations of cavitation flow and hull pressure fluctuations will be performed in the designing process to minimize the noise and vibration the propeller brings on board. Design and manufacture the propellers with low vibration & noise levels and no harmful cavitation.

Take materials seriously

Fountom chooses high-purity copper to build your propellers and rejects recycled low-purity coppers, which brings better propeller strength, yet smaller weights to the finished propeller.

Truly your propeller -warranted

Amongst hundreds of shipowners, shipping consultants, or even shipyards that order propellers from Fountom, quite many barely keep propeller design copies. The absence of the approved propeller design brings big trouble in propulsion system maintenance, repair, and replacement. Fountom always sends you the approved copies of propellers, and keeps a full record. Each propeller shall have a warranty period of 12 months since vessel sea trial, Fountom is confident and responsible for what it sells.

Tip To know more of our propeller manufacturing process, please go to Mrine Wiki > Process of manufacturing marine propeller.

Propeller Shaftline

Each vessel has its unique propulsion shaftline system, the typical parts include thrust shaft, intermediate/stern shafts, bearings, couplings, and seals. Propeller shaftline is simply structured, yet it is quite crucial for safe sailing. Fountom designs the most applicable shaftlines for your vessel based on the whirling vibration requirements of shipping class societies.

Got a project? Why Not get Fountom specialist to help right now

Fountom is professional in designing and manufacturing huge propellers, contact us or visit us for a reliable partnership now.

- For New Vessel simply leave us a message, or FILL US WITH MORE DETAILS OF YOUR PROJECT HERE. You may have our response in 24 hours.

- For Replacement: approved drawing is not a must-have but highly suggested for replacement propellers. With the approved drawing, Fountom can start manufacturing the identical propeller immediately.